Last modified on March 12, 2024

Standardisation Bodies

Modern infrastructure will increasingly incorporate new components which increase the robustness of the system. The future of CAD is bright and offers the long-term promise of mobility that improves safety and transport operations while lowering the environmental impact. Therefore, at this point, we have to see a more standardised and active automated ecosystem. Providing a common interface to improve the economy of scale to reduce cost, which improves the integration of advanced functions in CAD. At global and European level, different standards developing organizations exist with the intend to inform wider industry thinking and accelerate the successful introduction of exciting pioneering technology.

| Name | Description | Link |

|---|---|---|

| AASHTO | American Association of State Highway and Transportation Officials | view details |

| ANSI | American National Standards Institute | view details |

| ASTM | American Society for Testing and Materials | view details |

| ASAM | Association for Standardisation of Automation and Measuring systems | view details |

| BSI | British Standards Institution | view details |

| CEN | European committee for standardisation | view details |

| CENELEC | European committee for Electrotechnical standardisation | view details |

| CEPT-ECC | Electronic communications committe | view details |

| DIN | Deutsche Institut für Normung e.V | view details |

| DKE | Deutsches Kommission Electrotechnik | view details |

| ETSI | European Telecommunications Standards Institute | view details |

| IEC | International Electrotechnical Commission | view details |

| IEEE | Institute of Electrical and Electronics Engineers | view details |

| ISO | International Organization for Standardisation | view details |

| IETF | Internet Engineering Task Force | view details |

| ITU | International Telecommunications Union | view details |

| JISC | Japanese Industrial Standards Committee | view details |

| NEMA | National Electrical Manufacturers Association | view details |

| NISO | National Information Standards Organisation | view details |

| SAE | Society of Automotive Engineers | view details |

Society of Automotive Engineers (SAE)

SAE Level of automation

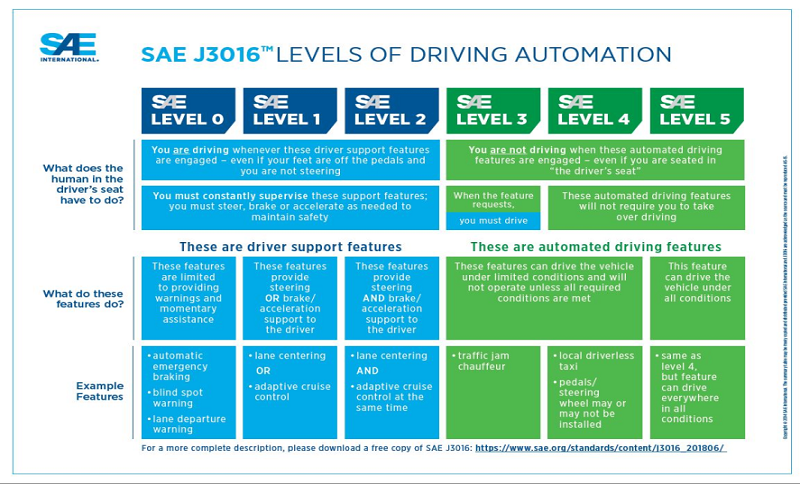

SAE International recently unveiled a new visual chart designed to clarify and simplify its J3016 “Levels of Driving Automation” standard for consumers. The J3016 standard defines six levels of driving automation, from SAE Level Zero (no automation) to SAE Level 5 (full vehicle autonomy). It serves as the industry’s most-cited reference for automated-vehicle (AV) capabilities.

J3016 provides and defines the six levels of driving automation, from no automation to full automation. Consistent with industry practices, the standard helps to eliminate confusion by providing clarity.

The new revisions, while substantial, preserve the original SAE J3016 level names, numbers, and functional distinctions, as well as the supporting terms. However, the new, revised version:

- Clarifies and rationalizes taxonomical differentiators for lower levels (levels 0-2)

- Clarifies the scope of the J3016 driving automation taxonomy (i.e., explains to what it does and does not apply)

- Modifies existing, and adds new, supporting terms and definitions

- Adds more rationale, examples, and explanatory text throughout

Automated Vehicle Safety Consortium™ (AVSC)

This is an industry program of SAE Industry Technologies Consortia® (SAE ITC) focus on advancing standards for automated driving vehicles. In particular, the consortium will concentrated the effort on develop safe and reliable vehicle at SAE level 4 and 5.

International Organization for Standardisation (ISO)

ISO is an independent, non-governmental international organisation with a membership of 164 national standards bodies.

The objective of the experts that participate in the different working groups is to share knowledge and develop voluntary, consensus-based, market relevant International Standards that support innovation and provide solutions to global challenges.

The ISO/TC 204 technical committee is taking care of the standardisation of information, communication and control systems in the field of urban and rural surface transportation, including intermodal and multimodal aspects thereof, traveller information, traffic management, public transport, commercial transport, emergency services and commercial services in the intelligent transport systems (ITS) field.

ISO/TC 22 develops standards of all aspects for all types of road vehicles and their interfaces approved for operation on public roads for the whole life cycle concerning safety, security, sustainability, compatibility, interchangeability, maintenance, evaluation of performance and quality. ISO/TC 22 consists of 11 subcommitees and also includes the automated driving coordination group (ADCG):

| ISO/TC 22/SC 31 | Data communication |

| ISO/TC 22/SC 32 | Electrical and electronic components and general system aspects |

| ISO/TC 22/SC 33 | Vehicle dynamics, chassis components and driving automation systems testing |

| ISO/TC 22/SC 34 | Propulsion, powertrain and powertrain fluids |

| ISO/TC 22/SC 35 | Lighting and visibility |

| ISO/TC 22/SC 36 | Safety and impact testing |

| ISO/TC 22/SC 37 | Electrically propelled vehicles |

| ISO/TC 22/SC 38 | Motorcycles and mopeds |

| ISO/TC 22/SC 39 | Ergonomics |

| ISO/TC 22/SC 40 | Specific aspects for light and heavy commercial vehicles, busses and trailers |

| ISO/TC 22/SC 41 | Specific aspects for gaseous fuels |

There are several work items in development for a number of ADAS and AD features that have relevance for high automation. For more information on specific ISO standards related to automated vehicles please check the standards list’s page.

British Standards Institution (BSI)

The British Standards Institution (BSI) is the national standards body of the United Kingdom. BSI has written several fundamental principles of automotive cybersecurity in order to help all parties involved in the vehicle lifecycle and ecosystem understand better how to improve and maintain vehicle security and the security of associated intelligent transport systems (ITS).

Feedback form

Have feedback on this section??? Let us know!

Feedback

Please add your feedback in the field below.

Your feedback has been sent!

Thank you for your input.

An error occured...

Please try again later.